Introduction

DoBeny's new miniature, high performance Non-contact Infrared Two Laser Temperature Sensor IRT-LAS series is best used for measuring high temperature and small size objects.

DoBeny’s family of infrared non-contact sensors have no drift and have high repeatability & interchangeability giving them the edge needed to increase production process speed and quality.

Infrared Two Laser Temperature Sensor IRT-LAS series are best for measuring high temperature metals(Foundry,Sinter Plant,Blast Furnace,Continuous Casting Processing,Forging,Metal Packaging ,High Temp Heat Treating,Hot Forming Steel Panels

,High Precision Heat Treatment in Vacuum Carburizing,High Temperature Vacuum Heat Treatment,Fasteners Heat Treatment - Hydrogen Embrittlement,Hot Rolling Mills,Tube and Pipe Mills,Rod and Wire Mills,Galvanizing and Annealing Lines,Aluminum Brazing ,Aluminum Processing,Aluminum Solution Reheat)

· non-contact

· Output: 4 to 20 mA

· interface directly to most of all meters, controllers, dataloggers

· Fast Response 5ms with High Stability

· Strong anti-interference ability, not disturbed by induction heating magnetic field

· Dual laser aiming, more convenient temperature measurement and more accurate aiming.

2.General Specifications

Temperature Range: See To Order chart

Supply Voltage: 24 VDC

Output: 4 to 20 mA

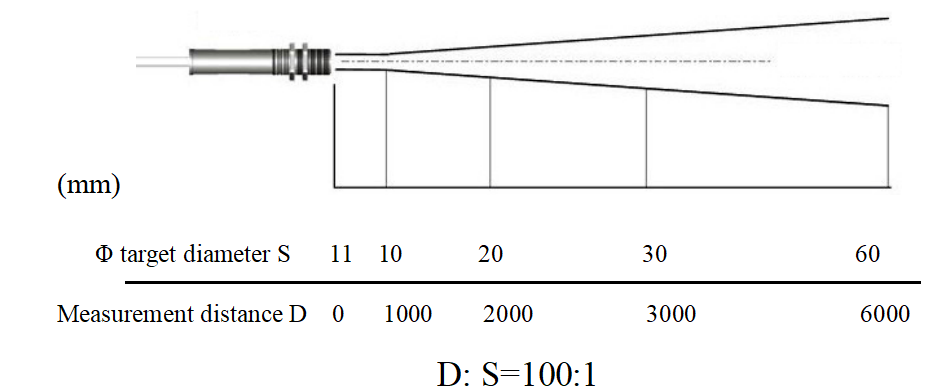

Field of View: 100:1

Accuracy: ±1% or ±1℃ , whichever is greater

Repeatability: ±1% or ±1℃

Response Time: 30ms

Maximum current: 50mA

Spectral wavelength: 1.6μm/1.0μm

Emissivity: 0.95

Construction: Stainless Steel 304

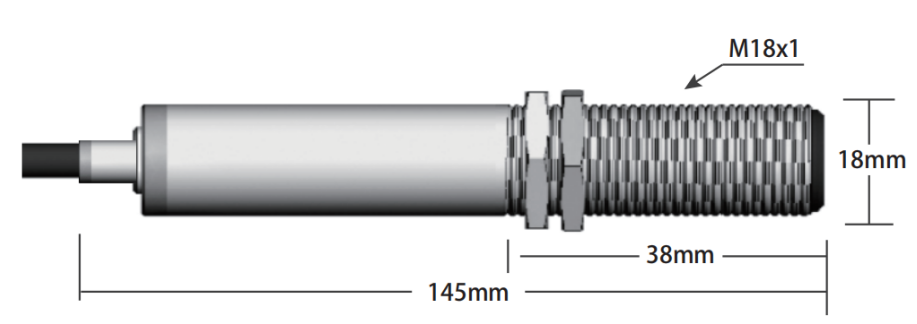

Dimensions: ø18 x length145 mm

Mounting: two mounting nuts

Cable Length: 2m as standard (custom lengths also available)

Weight: 400g with 2 m(7') cable

Environmental Rating: IP65

Ambient Temperature Operating Range: 0 to 50°C (32 to 122°F)

4-wire , 3-wire or 2-wire ( freely)

Overall dimensions

Field of View:

3. Operating principle and precautions

a.Principle of infrared temperature measurement

Any object will emit infrared energy externally and radiation intensity changes with temperature. The Infrared Two Laser Temperature Sensor IRT-LAS series is usually used for measuring infrared radiation energy which wavelength is within 0.8μm-18μm.

Infrared Two Laser Temperature Sensor IRT-LAS series is a photoelectron sensor which receives infrared radiation and converts it to electrical signal, displays or outputs temperature by linear signal processing by line amplifier.

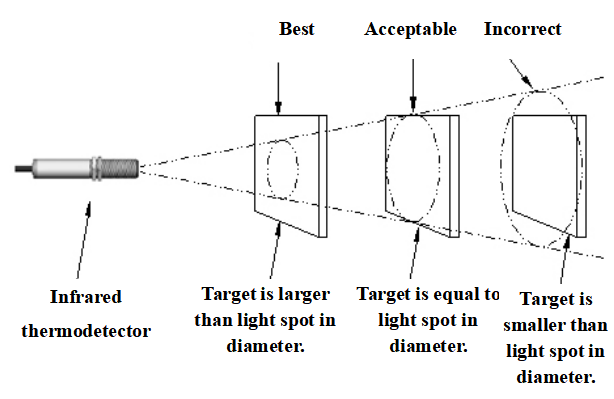

b.Maximum distance and size of measurement point

Size of measurement target and optical features of infrared thermodetector determine maximum distance between measurement target and measurement head. To prevent measurement error, the measurement target should fill field of view of probe as much as possible. Therefore, always keep measurement point smaller than measurement object or at least the same size as measurement target.

c.Environment temperature

Series IRT-LAS infrared thermodetector can work within environment temperature 0--50℃, otherwise use cooling protection jacket.

d.Cleaning lens

Keep instrument lens clean and prevent measurement error or damage or lens caused by dust or smoke. If there is dust accumulated on the lens, wipe it clean with lens wiping paper dipped with anhydrous alcohol.

e.Electromagnetic interference

To prevent electromagnetic interference, please take the following measures:

The infrared thermodetector should be installed in a place away from electromagnetic field (such as electric motor, motor and high power cable). Add metal sleeve is necessary.

4. Installation

a. Mechanical installation

Series L metal housing has M18×1 thread which can install directly or use installation support. The adjustable installation support makes it easier to adjust measurement head.

When adjust measurement target and measurement head, ensure that optical path is barrier free, as shown below:

Ordering information IRT(Field of View)-LAS(Pre-Calibrated Temperature Range)AH-Cable Length.

Ordering Examples: IRT-LAS1200AH-02,Field of View:100:1, 350 to 1200°C, 2m

|

To Order |

|

|

Model No. |

Description |

|

IRT[*]-LAS[**]AH-[***] |

Infrared Two laser Temperature Sensor LAS Series |

|

Field of View [*] Select |

|

|

100 |

100:1 |

|

|

|

|

Temperature Range [**] Select |

|

|

1200 |

350 to 1200°C |

|

1400 |

400 to 1400°C |

|

600 |

600 to 1700°C |

|

2000 |

700 to 2000°C |

|

2400 |

1100 to 2400°C |

|

|

|

|

Cable Length [***] Select |

|

|

02 |

2m(7') |

|

05 |

5 m (16') |

Technical Experts at Your Service Call 86-18257343661(WeChat) from 8 AM—5 PM China for applications and technical support, or email dobeny@126.com, you will have a response within 24 hours.

Contact: Yang Wanlu

Phone: 18257343661

Tel:

Email: dobeny@126.com

Add: Zheshang Mansion, No.8 Jingdu 3rd Road, Zhejiang Haining Jingbian Industrial Park, Haining, Jiaxing,Zhejiang